Class 12: Molding & Casting

5 minute read

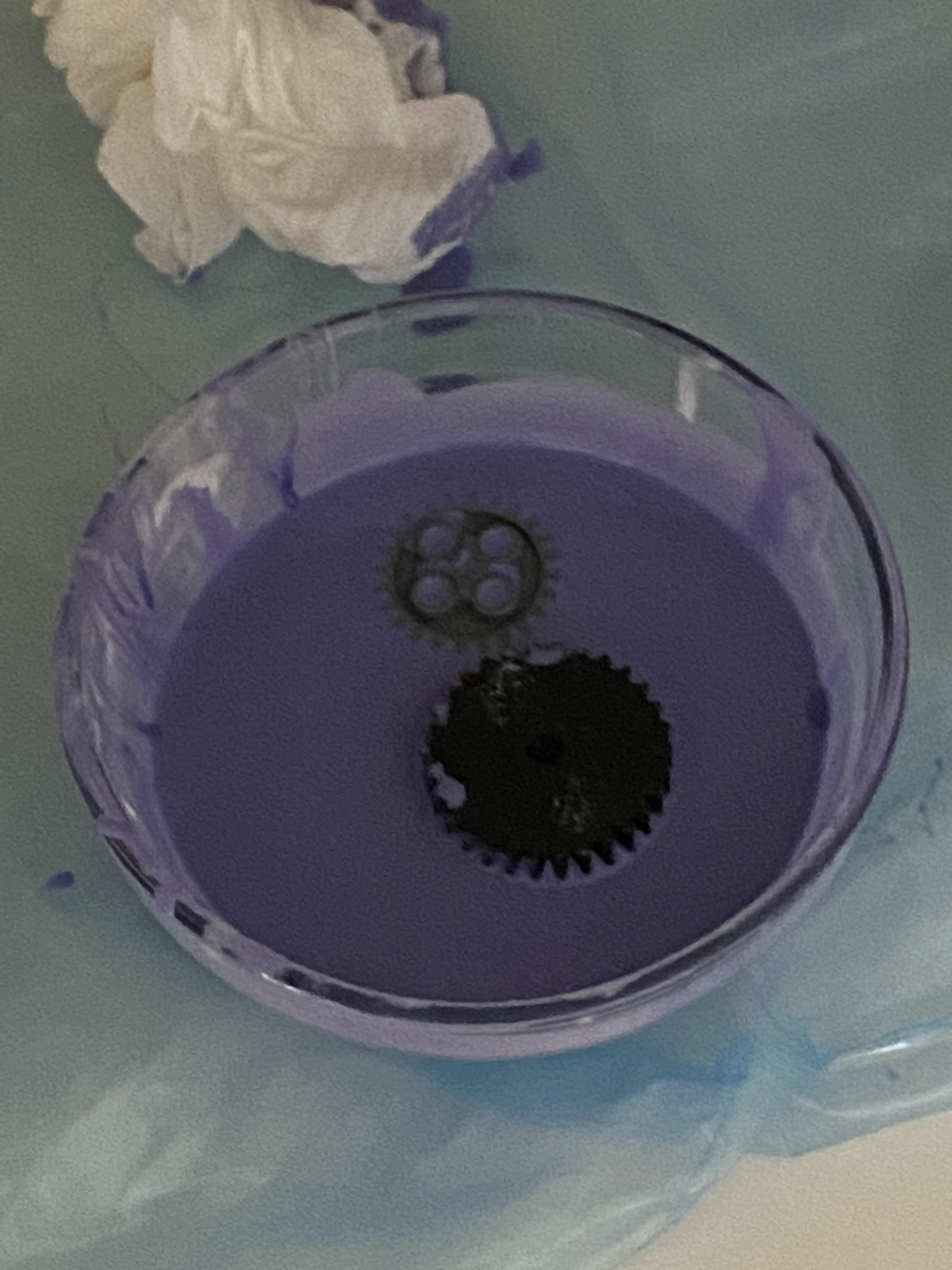

I first tried casting, planning to make some ice gears, but unfortunately I couldn't get the gears out of the mold. Very unfortunate.

On a much cooler note, I made my first soft robotics actuator! I got some Ecoflex 00-30 (silicone rubber cast) and poured it into a cardboard mold (my 3D printer was unavailable at the time, unfortunately). My professors were kind enough to send me a DC motor pump which I used to regulate the pneumatics of it. It was tons of fun, check out the image gallery for my failed mold and successful actuator! I followed a YouTube tutorial, except that I changed some of the measurements because his were too large. I originally was trying to make this the gripper arm of the robot but it was impractical.

A little crash course on actuators and soft robots. The actuator I made is called a fiber-reinforced actuator, which essentially means a side of the actuator that is super flexible, stretchy, and inflatable like a balloon and another side that is a lot more rigid. When there is increased air pressure it means that the top side will inflate while the bottom doesn't, leading to a curling motion. This is also explained in the YouTube tutorial I linked earlier. It's cool stuff!

If I had more time I'd put zipties around it so that it would inflate more like a grabber and less like a balloon, but I didn't have the time because casting takes a long time. That's my next goal, however.

As viral rapper MoneyMarr once said: "Mix it, mix it, mix it, mix it / Mix it, mix it, mix it, mix it / Mix it, mix it, mix it, mix it"

Tragedy strikes, Circa 2021. I literally tried everything, from an exacto knife to flathead screwdrivers, to no avail.

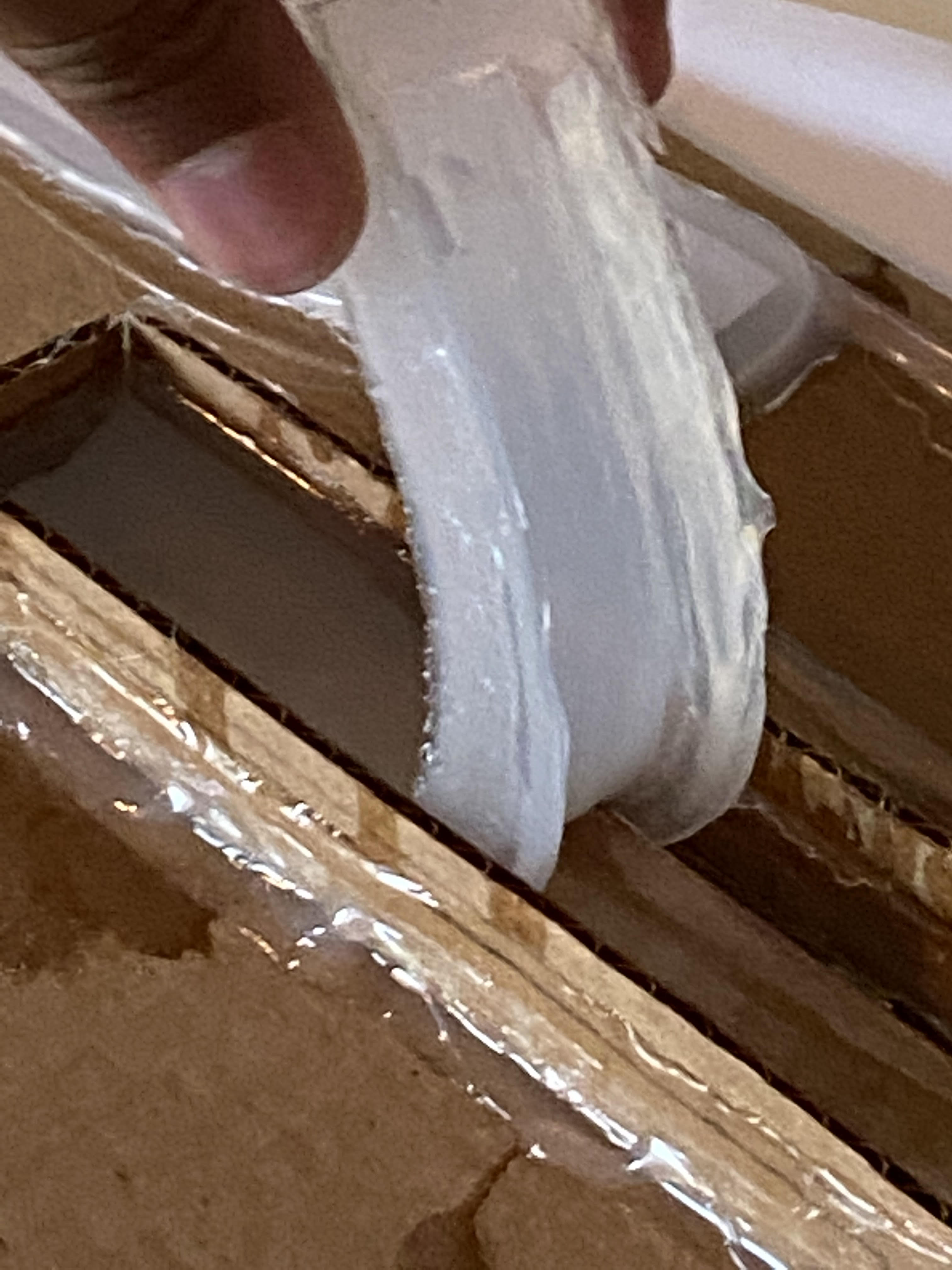

Here I filled the cardboard molds with my Ecoflex! I was very excited. The cardboard molds were literally made of cardboard and hot glue. I used two-three layers of hot glue on everything to make sure no silicone seeps through.

Pulling out the stretchy top part of the actuator. I forgot to use gloves, fortunately my skin was okay!

The next part is sticking the top cast to the bottom. So, you put more ecoflex on the bottom as an adhesive, since any other material would impair the function of the actuator due to it being more rigid.

I also coated the inside of the top part of the actuator with an extra batch of silicone to smooth out the imperfections caused by the cardboard mold I used. After that, I stuck them together, waited, pulled them out, and stuck a tube into them. I forgot to take photos of that, sorry. There's a video down below of the finished product!